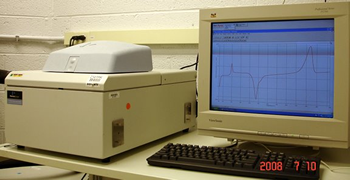

CLIENT-RUN INSTRUMENT

TRAINER: KIRAN SUBEDI

Differential Scanning Calorimeter (DSC) measures the amount of energy (heat) absorbed or released by a sample as it is heated, cooled or held at a constant (isothermal) temperature. The precise measure of sample temperature is also made with a DSC. It is used for the calorimetric measurement, characterization, and analysis of thermal properties of materials. Types of thermal analysis measurement typically performed by DSC would be as follow: Melting, Crystallization, Glass Transition, Polymorphism, Purity, Specific Heat, Kinetic Study and Curing Reaction

Differential Scanning Calorimeter (DSC) measures the amount of energy (heat) absorbed or released by a sample as it is heated, cooled or held at a constant (isothermal) temperature. The precise measure of sample temperature is also made with a DSC. It is used for the calorimetric measurement, characterization, and analysis of thermal properties of materials. Types of thermal analysis measurement typically performed by DSC would be as follow: Melting, Crystallization, Glass Transition, Polymorphism, Purity, Specific Heat, Kinetic Study and Curing Reaction

The Diamond DSC is designed using the unique power compensation approach, which yields true heat flow measurements. Because of the very low mass (<1g) and independent furnace design of the power compensation approach, the Pyris Diamond DSC provides both the necessary very high sensitivity and unsurpassed resolution necessary for the measurement of polymorphism exhibited by pharmaceuticals.

The Diamond DSC offers the following key features:

- Very high sensitivity for the detection of weak transitions or small polymorphic forms

- Outstanding and unsurpassed resolution for better separation of polymorphic melting peaks

- The fastest heating and cooling (up to 500ºC/min) to better study kinetic or time dependent effects

- Use of platinum resistance thermometer (PRT) for the measurement of sample temperature which provides better accuracy and reproducibility than thermocouples

- Very stable baseline performance

Specifications

- DSC Type: Power-compensation temperature null principle. Measures temperature and energy directly, rather than differential temperature (DT).

- DSC Cell: Independent dual furnaces constructed of platinum-iridium alloy with independent platinum resistance heaters and temperature sensors with furnace mass less than 1g.

- Temperature Sensor: Distributed, Platinum Resistance Thermometers for best linearity.

- Temperature Range: -70ºC to 730ºC

- Calorimetry Accuracy / Precision: < ± 1% / < ± 0.1%

- Scanning Rates Heating/Cooling: 0.01ºC to 500ºC/min

- Cooling Option: Intracooler 2P, -70ºC to 730ºC

Sample Preparation

The differential scanning calorimeter can analyze solid or liquid samples. Solid samples can be in film, powder, crystal, or granular form. Although quantities accuracy will remain the same regardless of sample shape, the qualitative appearance of run may be affected by the sample configuration. Proper sample preparation that maximizes the contact surface between the pan and the sample will reduce the resistance of the sample to heat flow though the DSC temperature sensors and will result in maximum peak sharpness and resolution. The best sample shapes for optimum performance are thin desks or film or fine granules spread in thin layer on the bottom of the pan. Materials such as polymer films can be conveniently prepared by cutting out sections of the film with a standard paper punch or cork borer. Solid materials can be sliced with a razor or knife.